Grinding

Flat and Spherical Metal Grinder(with auto stocker)

MZ1-30A

A surface grinding machine with an automatic carrying stocker that is concentrating lens processing know-how.

It can realize spherical or surface grinding for metal parts with a cup wheel.

Considering the maintainability, the setup is accessible from the front side.

In addition, by incorporating optional software, the mold of the brittle material used in the mold press molding also can be ground to the aspherical shape.

It can realize spherical or surface grinding for metal parts with a cup wheel.

Considering the maintainability, the setup is accessible from the front side.

In addition, by incorporating optional software, the mold of the brittle material used in the mold press molding also can be ground to the aspherical shape.

Feature

- Use a cup-shaped ToolCombine our long experiences in Lens processing technology into metal grinding industry

- Vertical type, Space saving

- Auto measuring functionAutomatically re-correct thickness by offsetting abrasion of tool

- Interactive NC system, User friendly

- Better MaintainabilityOperate from front side, Easy setup

- The auto-stocker is easily removable, provide an efficient way to set-up when changing production

Spec

| Number of wheel axis/processing configuration | 1-axis/vertical automatic machine | |

|---|---|---|

| Processing surface | 1 surface 1spindle | |

| Control system | NC | |

| chucking technology | Air chuck | |

| Supported workpiece diameter | ϕ8 ~ ϕ30 | |

| Supported workpiece curvature | ±SR4 ~ ∞ | |

| Infeed axis | workpiece head | |

| Infeed drive | Servo motor | |

| Max. grinding wheel diameter | ϕ60 | |

| Max. cutting capacity | 30mm | |

| Workpiece spindle rotation | 15 ~ 1,500min-1 | |

| Wheel spindle rotation | 1,000 ~ 15,000min-1 | |

| Workpiece spindle nose shape | NT#35 (2face constrained) M22P1.5 | |

| Wheel spindle nose shape | (standard)ϕ20×1/7.5taper M22P1.0 (sub-standard)ϕ15.5×1/7.5taper M12.5P1.0 |

|

| Wheel spindle drive electric motor | 0.5kW(Servo motor) | |

| X travel | -50 ~ 100mm(Servo motor) | |

| Spindle circular angle | 0 ~ 40˚(Servo motor) | |

| Work head travel | 110mm(Servo motor) | |

| Workpiece spindle travel distance | 50mm(Air cylinder) | |

| Cross axis accuracy | 0.0001mm/P | |

| Circular axis accuracy | 0.0001˚/P | |

| Infeed axis accuracy | 0.0001mm/P | |

| Process data memory | 30surfaces | |

| Feeding/Storage | 1stage 2pallets | |

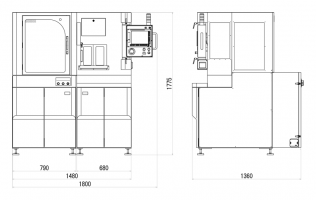

| Size | Width(W) | 680mm(1,480mm) |

| Depth(D) | 1,360mm(1,360mm) | |

| Height(H) | 1,775mm(1,775mm) | |

| Weight | 900kg(1,400kg) *1 | |

| Power supply | AC200V Three-phase 10kVA | |

| Air supply | 0.4 ~ 0.5MPa | |

|

In the dimension data, what noted in brackets means stocker’s size Standard machine specs might not be able to process works with particular Diameter or Curvature |

||

Dimensions

zoom

zoom- For option details, please make inquiry.