Tool presetter

Tool presetter

HP-6040V-FA

Automatic measuring system(With cutting tool replacement unit)

Component part

- Tool Presetter [HP-6040V]

- According to the registered measuring program, tool diameter, length, runout, shape , and cutting tool edge wear will be measured fully automatically.

- The second camera is used to read the tool ID (code) and check the shape of cutting tool edge.

- The second camera can rotate 90°, so the shape of the cutting tool edge can also be chekced from above.

- Tighten/Loosen unit

- It is a unit which can change cutting tools such as collet chucks and milling chucks automatically.

- With the tool information (nut position, set torque) from the database, the claws moves automatically to the nut position and tightens the nut with the optimal torque.

- Holder/Cutting tool stand

- The articulated robot removes the holder and cutting tool.

- It is also impossibe to use a cart or a palette.

- Holder cleaning unit

- It is equipped with a rotating mechanism to remove dirt and foreign material, such as coolant and dust attached to the tapered part of the holder before puting to the tool presetter.

- Spindle cleaner

- Removes dirt and foreign material attached to spindle of the tool presetter regularly.

- Articulated robot

- It handles all transport within the system, including tooling transfer to the tool presetter, cutting tool removal, and cleaning.

- The combined hand can hold holder and cutting tool.

- It can replace the hand by hand changer, so it is able to correspond to different spindle sizes.

- Touch panel monitor

- Display the process of the automatic measuring system.

- Display the result of the measurment and the judgement of OK/NG.

Spec

| Measuring motion method | Electrical control |

|---|---|

| Measuring range | Length direction(Z axis):50 ~ 600mm Radial direction(X axis):-Φ50 ~ Φ400mm |

| Min value of counter reading | Length direction(Z axis):0.001mm Radial direction(X axis):Φ0.002mm |

| Air supply | 0.4MPa(4kgf/cm2) |

| Camera pixels | Approx 20K |

| Real viewing field | 5×7mm |

| Attach and release | Air |

| Power supply | AC100V |

| Weight | 400kg |

| Shank size | BT50, BT40, BT30, 25T, S20T, HSKA125, HSKA100, HSKA63, HSKA50, HSKA40, HSKA32(HSK32 is only for tools other than center-through type) Choose one shank from the size list above,if it is BT shank,please check the type of stud bolt. |

| Standard bar(Wooden box) | Shank size: 1piece If it is BT shank,please check the type of stud bolt. Stud bolt is prvoided for BT shank only. Please designate the stud bolt type. |

|---|---|

| Cover | 1pcs each for Spindle, Machine body, Screen |

| Quick sleeve | BT or HSK Corresponding to various size(please check the tool shank size) |

|---|---|

| Tool manager | A system that transfer the necessary tool date to machining center directly during the processing. Detailed specifications need to be negotiated separately. |

| Tool management database | Logging in,reading and calling out the tool information. |

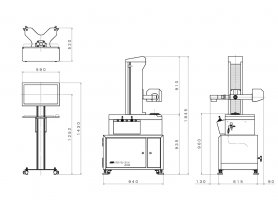

Dimensions

zoom

zoom