Stir&defoam machine

What is Rotation

&revolution mix&defoam machine?

Rotation&revolution mix&defoam machine Hi-Merger

Hi-Merger is device that the materials are self mixed and defoamed in containers with a convection flow created by high speed rotation and revolution. No propeller is used, greatly reduce damages to materials.

Hi-Merger can process a wide range of materials such as medical materials, inks and paints, cosmetic base materials, resins, adhesives, sealents, and secondary battery materials. It is also used in various industries such as researches and developments and manufacturing sites.

Mechanism of mixing and defoaming

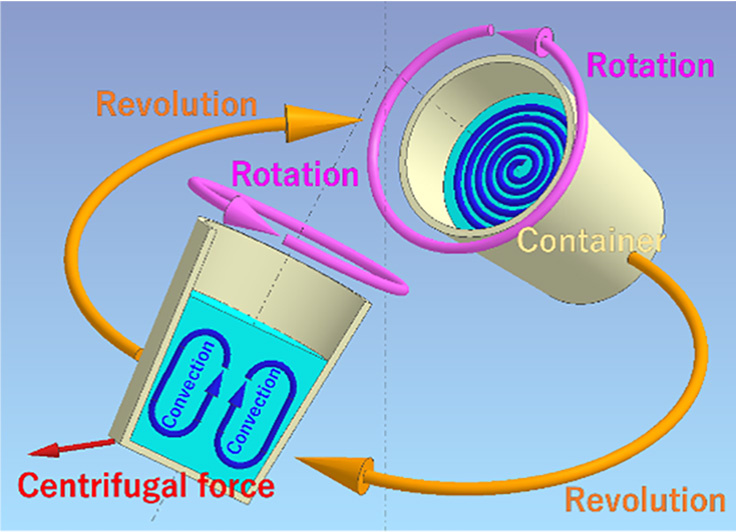

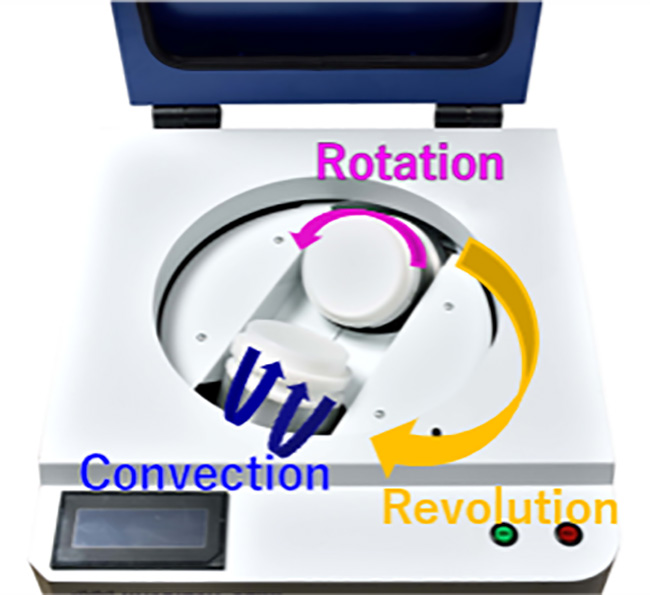

Hi-Merger is mounted tilted the container containing the material inside the device and given rotation and revolution motion to create a planetary motion(Fig. 1).

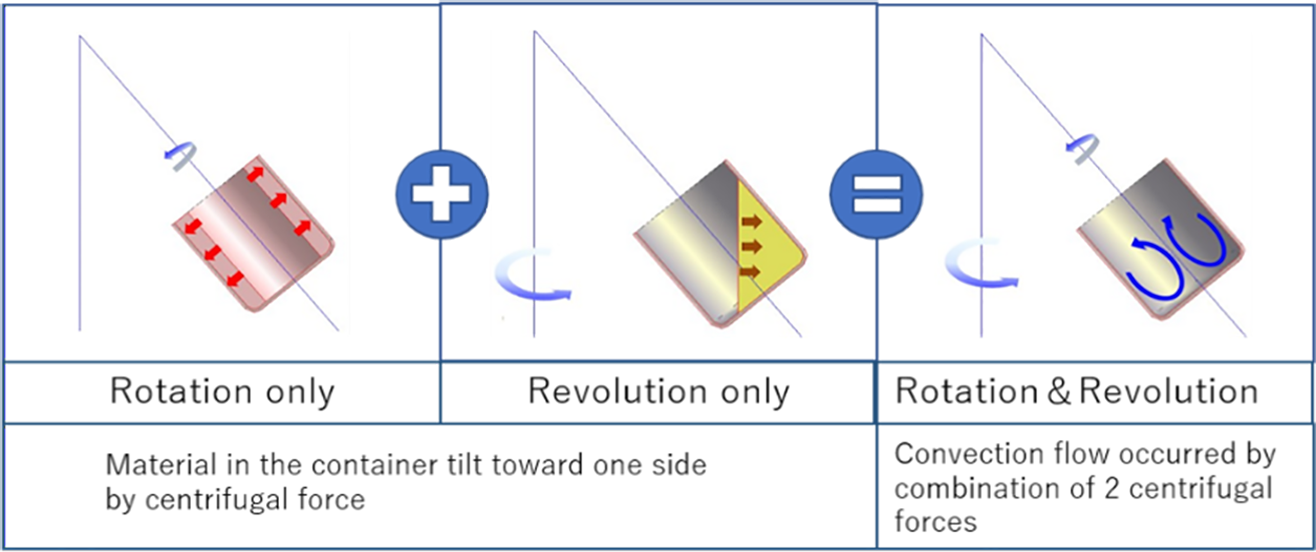

Large centrifugal force is generated when the container is orbited at high speed, and when added to the centrifugal force from its own rotation, a strong synthetic centrifugal force acts on the material inside (Fig. 2).

The material attempts to move along the inner wall of the container to the bottom because the synthetic centrifugal force acts radially downward on the inner wall of the cylindrical container. As the container rotates on its own axis, the material continuously flows downward on the inner walls of the container and upward in the center, and the rotation of the container also generates vortex flow, resulting in a convective motion.The effective synthesis of these two flows results in dense mixing.

Air bubbles mixed in the material gather at the center due to centrifugal force and rotation movement, and are pushed up to the surface from the inside by convection currents. At the same time, the bubbles are compressed and defoamed by strong centrifugal force. If these operations are performed in a vacuum, even finer bubbles can be defoamed.

Advantages of introducing mixing and defoaming machine

Mixing and defoaming machine of KYORITSU SEIKI can solve the following troubles

No material loss

Hi-Merger can reduce material loss and damage when processing materials because there is no propeller used.

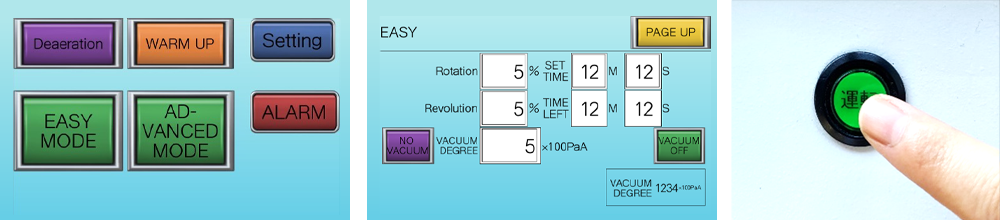

Prevents clumps*1and insufficient mixing of materials.

It is possible to change the ratio of rotation and revolution speed freely, and the mixing and defoaming conditions can be set by the viscosity and quality of the material. In addition, it will produce a large centrifugal force of up to 400G, so that it can guarantee high mixing power.

*1:Clump is that powder such as flour to be solidified when dissolve in liquid.It is because the powder and the liquid are not mixed well.

High viscosity material can be processed efficiently.

The model which equipped with the first mechanical transmission unit in the industry was released in 2023.

The ratio of rotation and revolution(110 ways) can be freely adjusted and stable operation can be achieved from high speed to ultra-low speed.

High viscosity material also can be processed efficiently.

There are various lineups from small tabletop machines to large, high-capacity machines (Max. 40ℓ batch).

It is a device that can easily and efficiently perform high-precision mixing and defoaming of liquids and slurries. It also can maximize the original ability of materials.

The desired container can be used.

It can respond to the customer`s needs and make the best suggestions.

We can provide demonstration machine and processing test at any time, so please tell us your request.

Designing, manufacturing, and after follow are integrated into our own company,so that we can repond you quickly.