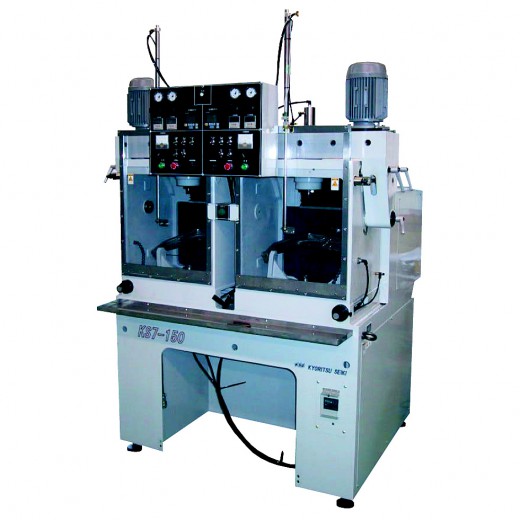

Grinding

Large High-Speed smoothing and polishing machine

KS(P)7-150

Feature

- 2 spindles each with independent function

- Capable of processing small lens by applying low pressure.

- Totally water-proof measure for security concern

- High rigidity, high stability, high accuracy

- Automatic pressure changing systemPressure is changeable according to lens type during processing

- Universal polishing techniqueSupport a wide range of curvature

Spec

| Processing method | Universal | |

|---|---|---|

| Spindle | 2-axis(1-axis 1-drive) | |

| Maximum workpiece diameter | MAXϕ150 | |

| Supported workpiece curvature | ±SR32 ~ ∞ | |

| Distance between axes | 635mm | |

| Max. tool plate diameter | MAXϕ300 | |

| Tool spindle nose shape | ϕ28socket M26P3.0 | |

| Tool attachment axis | Upper spindle | |

| Main spindle tilt angle | 0 ~ 35˚ | |

| Main spindle tilt direction | fore and aft | |

| Swing distance | 0 ~ 40mm | |

| Number of swing cycles | 25CPM | |

| Workpiece spindle travel distance | ±75mm(fore and aft) | |

| Main spindle rotation speed | 450 ~ 1,800min-1(stepless inverter) | |

| Pressing pin shape(Pressure pin) | - | |

| Pressing pin adjustable amount | - | |

| Process load | 5 ~ 50kg | |

| Processing timer | 0.1seconds ~ 9,999hours | |

| Main spindle electric motor | 1.5kw x 2P | |

| Workpiece swing electric motor | 60W x 2P | |

| Coolant electric motor | 100W x 2P | |

| Size | Width(W) | 1,540mm |

| Depth(D) | 1,340mm | |

| Height(H) | 2,090mm | |

| Weight | 1,200kg | |